Before ensuring the power supply, the environment where the UPS will be placed should be examined for the following basic conditions:

Initially, the location where the UPS will be installed must have adequate space dimensionally for its installation.

The signs to look for in this regard are:

- UPS transport and removal.

- UPS (base) mounting address.

- Uninterruptible power supply.

- Anti-vibration.

- Noise level.

- Installation system.

UPS transport and removal

TESCOM's UPS is designed with the ultimate goal of making transport, removal, and installation easy and safe. To that end, both standard and modular UPS are designed with a metal base where casters are bolted for their handling.

Similar to the large, modular UPS, which needs to be moved with specialized handling equipment, using platforms that can handle the UPS from the base and support the entry of the tines.

UPS (base) mounting address.

The indication that the floor in the area needs to be addressed is when the weight to be supported by the floor is the most important parameter in this condition. This should be evaluated in advance and consideration should be given to the UPS's placement and handling.

Emphasis should be placed on the fact that the simplest way to strengthen the building is with solutions that will be implemented on the building's metal floor to the casters. It is imperative to consider that the result is well strengthened and that the stresses of the strengthening are appropriate in relation to the soil. Therefore, it may be helpful to seek an increase in the strength of the building and to improve the building-generator coupling. In this case, it is important that the area has adequate space dimensionally for the needs of the technicians.

Uninterruptible power supply

In critical installations, both standard and modular UPS offer very good value for money and reliability. For the selection of the appropriate UPS series, the parameters to be considered are:

- Cost view of purchase.

- View cost of use purchase.

- View cost of use installation.

It is vital that enclosed spaces have adequate air intake and exhaust to prevent the recirculation of hot air from the unit and the overheating of the generator, as this may affect the uninterrupted operation of the UPS due to thermal shutdowns. It is practically observed that the area of the UPS should have adequate openings with grilles. The size of the openings and the selection of the air conditioning unit should not be overlooked – the air conditioning of the area should not exceed 40 °C to avoid reducing the efficiency of the UPS.

You should not place the UPS in a confined space, as the air it draws from the environment, which will cool the internal hot air components, is being overheated.

Anti-vibration mounts

The UPSs that operate in areas with vibrations, if not properly insulated, may need to be moved to the surrounding area where they are installed, causing noise and vibration to the premises they support. To avoid this, they should be placed away from the UPS using anti-vibration mounts that can absorb the surrounding vibrations.

All TESCOM UPSs are equipped with anti-vibration mounts for both the generator-enclosure and the base.

For installations where this issue is particularly critical, anti-vibration mounts with air springs, elastic materials (e.g., Sylomer) are recommended, which dampen and absorb the vibration of the anti-vibration mounts.

Noise reduction

The noise emitted by a UPS is the sum of the mechanical noise and the noise of the various components of the equipment.

If there are many surrounding residents who are disturbed by the noise generated by the generator, it is possible to dampen the noise for measurement purposes.

Measures from the surrounding area where the UPS will be installed or from the air intake and exhaust openings are differential measures for the air path.

In hospitals or residential areas, the noise of the UPS is a major problem that needs to be addressed, and in these areas, TESCOM uses and provides solutions to minimize noise. These are:

- Sound-absorbing air diffusers (super silent type air intake)

- Enclosed exhaust silencers (critical silencer type)

- Double layer soundproofed material on the silencers (super silent type)

- Air diversion blades (super silent type)

Exhaust silencer system

To address the noise from the generators located near the generator, in addition to reducing the noise of the surrounding noise, it should be installed in an area to reduce the exhaust noise of the generators through the air ducts. Combination of location and silencers.

To ensure the quiet and complete operation of the generators, the TESCOM technical department will support the unique requirements of these generators to ensure the smooth operation of the equipment.

LEO LCD

LEO LCD

DS 300 H/HB

DS 300 H/HB

PRIME PLUS

PRIME PLUS

NEOLINE

NEOLINE

PRIME

PRIME

DS 300 SH/SHB

DS 300 SH/SHB

AVR 33

AVR 33

AVR 11

AVR 11

HYPERLINE

HYPERLINE

DYNAMIC BASIC

DYNAMIC BASIC

DYNAMAX

DYNAMAX

PROLINE B

PROLINE B

SAFEBOX B IP55 / OUTDOOR

SAFEBOX B IP55 / OUTDOOR

SAFEBOX B IP55 / INDOOR

SAFEBOX B IP55 / INDOOR

PROLINE

PROLINE

LP

LP

ES/ESC

ES/ESC

Connection Symbols

Connection Symbols

JACK KEYSTONE

JACK KEYSTONE

PATCH CORD CAT6A

PATCH CORD CAT6A

PATCH CORD CAT6

PATCH CORD CAT6

PATCH CABLE RAW

PATCH CABLE RAW

PATCH PANELS

PATCH PANELS

SWITCHES

SWITCHES

DIESEL / Baudouin

DIESEL / Baudouin

SINGLE PHASE

SINGLE PHASE

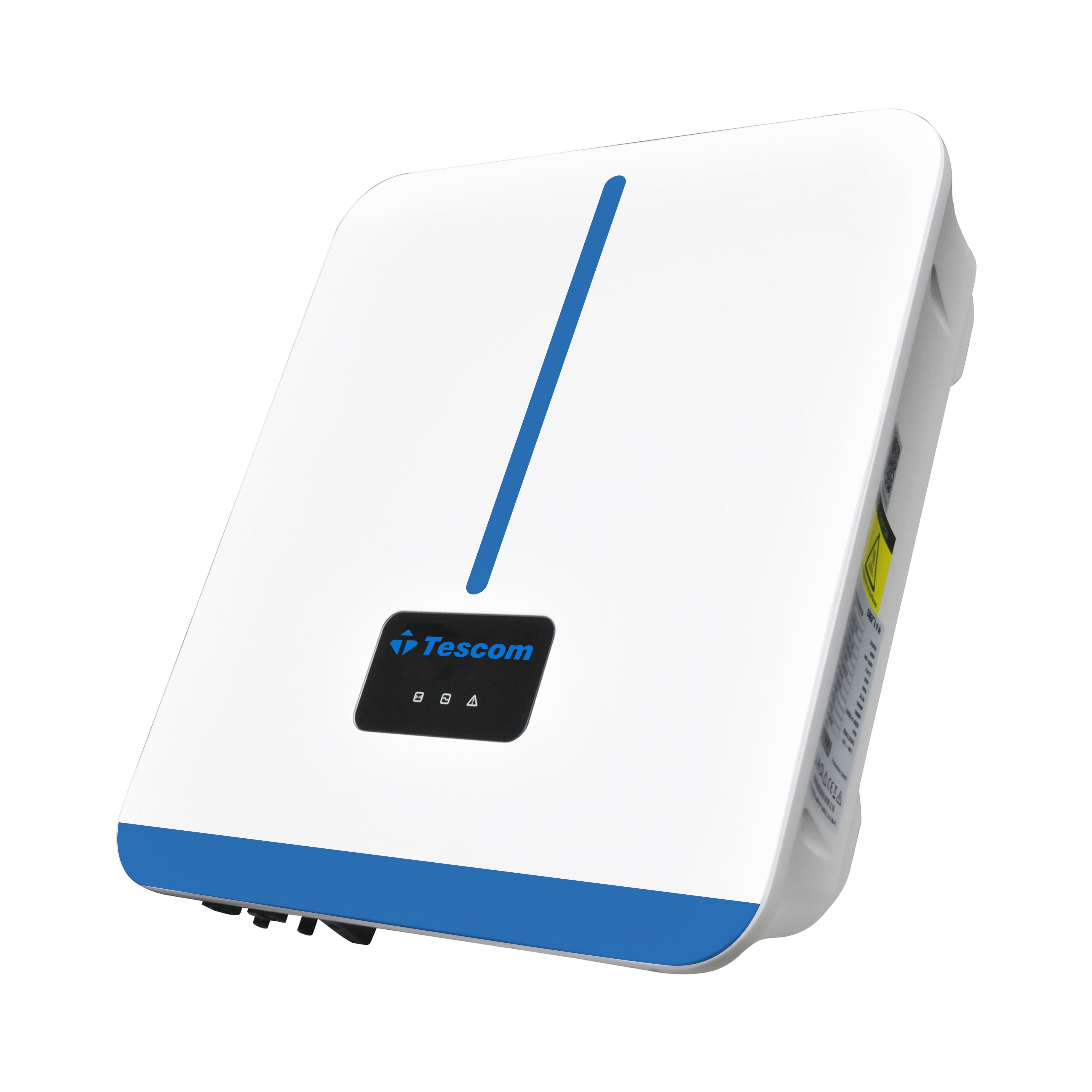

INVERTER 3phase

INVERTER 3phase

INVERTER 1phase

INVERTER 1phase

INVERTER Industrial

INVERTER Industrial

EV CHARGER

EV CHARGER